We introduce innovative Wet Abrasive Blasting technology, is a less aggressive form of blasting in comparison to dry blasting, working just as effectively.

The ricochet of media is reduced due to the cushioning effect created from the water acting as a lubricant between the media and the component surface. As a result, the angle of the media is changed, producing a lapping effect traveling across the surface, resulting in an even satin/ polished finish.

The illustrations below show the different processes of grit, bead, and wet-blasting;

Diagram 1

Diagram 2

Diagram 3

Unlike dry blasting where the finish is produced by sheer force of media impact, hydro-blasting does not allow for media to be impregnated into the component, nor is there any dust created by the break-up of media. In the full advantage of its dust-free, environmentally friendly process, as it means numerous tasks can be carried out simultaneously without the worry of dust spreading and impacting other areas of work.

The Hydro Abrasive Blasting System consume less quantity of abrasives in comparison with Dry Blasting System. The WAB System uses less quantity of water in comparison with UHP WJ System.

An innovative method of surface preparation especially for the confined spaces, tank interiors, plants like refinery, where there are many safety restrictions such as spreading of dust, generation of spark during surface preparation.

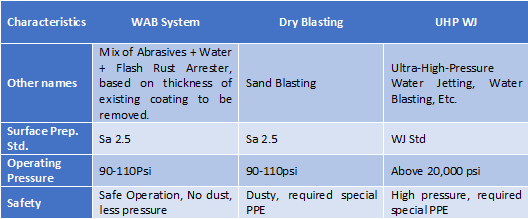

WAB System, hydro abrasive blasting system has following advantages over Dry Blasting and UHP WJ – Ultra High-Pressure Water Jetting operations towards surface preparation prior to coating/painting. Refer the tabulation;

Hydro Abrasive Blasting produces less dust. When blasting, dust is produced by the shattering of the dry abrasive particle and the substrate into small, airborne particles. When a wet particle shatters, the subsequent particle is enveloped in a water droplet. The additional mass weighs down the particle, causing it to fall to the ground. Hydro abrasive blasting has been proven to suppress dust up to 90% compared to dry blasting.

Less dust is not only safer, but it also requires much less /nil containment than dry blasting, which allows to take on jobs in situations where sandblasting isn’t feasible. Adding water is widely accepted as the most effective and efficient way to suppress dust.

SubDivo Specialist Services Division has the expertise and equipment to undertake Sa2.5 and Sa3 standards surface preparation and coating projects.

We make sure the debris and dust are controlled and surrounding areas have been protected by containment netting or encapsulation netting.

SubDivo Specialist Services Division has the expertise and equipment to undertake paint touch up work with Brush and rollers. SubDivo has the equipment for airless spray equipment and Hopper Gun Spray systems suitable for application of Anti-Skid Deck Coating as well.

SubDivo uses innovative equipment such as “power rollers” in order to minimize the paint spillage, wastage and easy to handle by our rope access crew as well.

We make sure the debris, dust and paint spillages are controlled and surrounding areas have been protected by containment netting or encapsulation netting.

We do have experienced rope access operatives who have handled the UHP WJ Nozzles with 30,000 psi at height of 100Mtrs on jack-up legs of an Offshore Rig.

We do undertake coating repair projects with ST2 Manual Surface Preparation and ST3 Power Tool Surface Preparation. Our professional rope access crew make sure the edges of spot prepared areas have been feathered, stripe coats being applied to corners, edges and other sharp areas prior to each coat of primer or intermediate or topcoat applications.

We do undertake decorative painting projects with our rope access crew. We design anchorage systems without damaging the roof structures of the buildings or other similar structures.

We offer decorative painting services to;